The Applications of Industrial ATX Motherboards in Manufacturing Processes

Industrial ATX motherboards are integral components in the manufacturing and automation sectors, providing the necessary infrastructure for complex industrial applications. These motherboards are designed to withstand harsh environments while delivering high performance, reliability, and flexibility. This article delves into the applications of industrial ATX motherboards in manufacturing processes, emphasizing their significance and versatility.

Understanding Industrial ATX Motherboards

What is an Industrial ATX Motherboard?

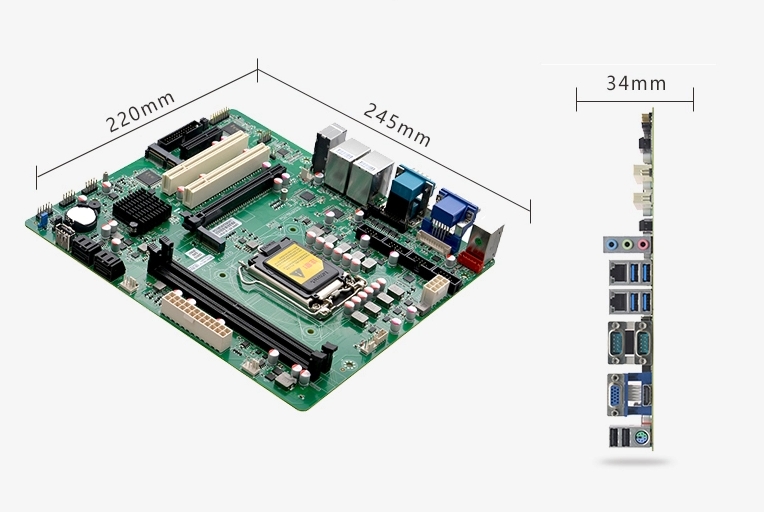

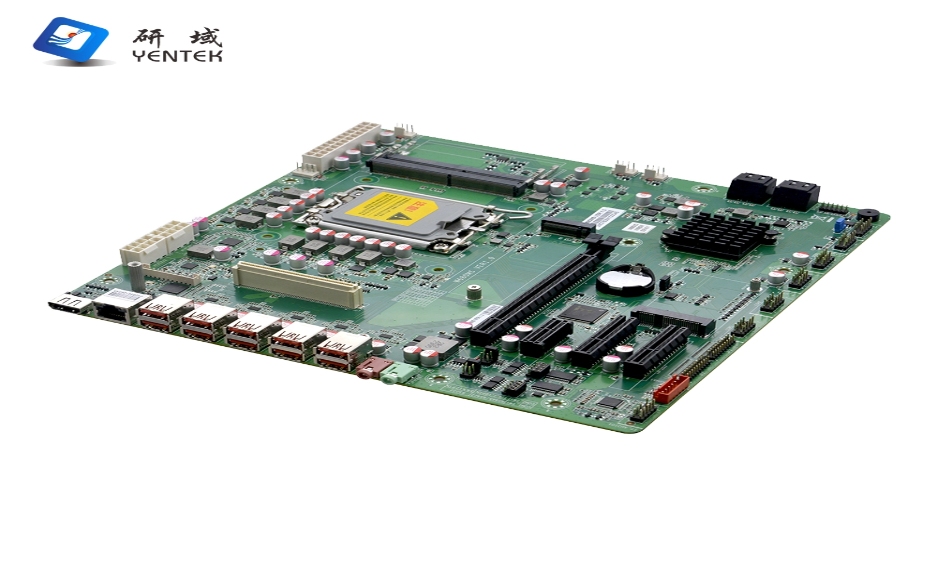

Industrial ATX motherboards are specialized computing boards designed to meet the rigorous demands of industrial environments. They are characterized by their robust construction, extended lifecycle, and ability to operate under harsh conditions such as extreme temperatures and vibrations. These motherboards support a wide range of processors and peripherals, making them suitable for various applications in manufacturing.

Key Features

Durability: Built to withstand environmental stressors.

Scalability: Ability to support multiple expansions for enhanced functionality.

Connectivity: Equipped with various I/O ports for seamless integration with other devices.

Performance: High processing power suitable for complex computations.

Applications in Manufacturing Processes

1. Automation Systems

Industrial ATX motherboards are pivotal in automation systems used in manufacturing. They control robotic arms, conveyor belts, and other automated machinery, enabling efficient production lines. By processing data from sensors and executing commands in real-time, these motherboards help streamline operations and reduce human intervention.

2. Data Acquisition Systems

In manufacturing environments, real-time data acquisition is crucial for monitoring production processes. Industrial ATX motherboards facilitate the collection and analysis of data from various sources, such as temperature sensors and pressure gauges. This capability allows manufacturers to maintain optimal operating conditions and quickly respond to any anomalies.

3. Machine Vision Applications

Machine vision systems rely on industrial ATX motherboards to process images captured by cameras on the production line. These systems are essential for quality control, enabling manufacturers to detect defects in products before they proceed to the next stage of production. The high processing capabilities of these motherboards ensure rapid image analysis and decision-making.

4. Inventory Management Solutions

Managing inventory efficiently is vital for any manufacturing operation. Industrial ATX motherboards are integrated into inventory management systems that track raw materials and finished products throughout the supply chain. This integration enhances visibility and control over inventory levels, reducing waste and improving resource allocation.

Advantages of Industrial ATX Motherboards

1. Customization Flexibility

One of the primary benefits of industrial ATX motherboards is their flexibility for customization. Manufacturers can tailor these boards to meet specific operational requirements by adding expansion cards or modifying configurations as needed.

2. Long Lifecycle Support

Industrial ATX motherboards are designed for longevity, which is essential in manufacturing where equipment replacement can be costly. Their robust design ensures they can operate effectively over extended periods without significant performance degradation.

3. Cost-Effectiveness

Compared to proprietary systems, industrial ATX motherboards offer a cost-effective solution for manufacturers. Their open architecture allows companies to source components from various suppliers, reducing overall costs while maintaining high performance standards.

Future Trends in Industrial ATX Motherboard Applications

1. IoT Integration

As the Internet of Things (IoT) continues to evolve, industrial ATX motherboards will increasingly support connected devices across manufacturing processes. This integration will enable more sophisticated data collection and analysis capabilities, leading to smarter manufacturing practices that enhance productivity and reduce costs.

2. Enhanced Security Features

With rising concerns about cybersecurity threats in industrial settings, future iterations of industrial ATX motherboards will likely include enhanced security features to protect sensitive data and systems from breaches.

3. Energy Efficiency Improvements

Sustainability is becoming a critical focus for many industries. Future developments in industrial ATX motherboard technology may emphasize energy efficiency, reducing power consumption while maintaining performance levels necessary for demanding applications.

Conclusion

Industrial ATX motherboards are indispensable tools in modern manufacturing processes, driving automation and enhancing operational efficiency across various applications. Their robustness, flexibility, and ability to integrate with advanced technologies position them as a cornerstone of industrial computing solutions provided by companies YENTEK®. As technology continues to advance, these motherboards will evolve further, addressing emerging challenges while supporting innovative manufacturing practices that meet the demands of a rapidly changing market landscape.

By leveraging the capabilities of industrial ATX motherboards, YENTEK® continues to lead the way in delivering high-tech solutions that empower manufacturers to achieve greater efficiency and productivity in their operations.

Exploring the Benefits of ATX Motherboards in Industrial Automation