Home > Application >Industrial Control

Industrial Control

- •Industrial control pain points

Technological update challenges, with the development of science and technology and industry, the industrial automation industry is also constantly upgrading. At present, the application of hot technologies such as robots, artificial intelligence, cloud computing, big data and other technologies that the industry is concerned about has developed to the stage of popularization. Simply rely on the basic technology application has been difficult to bring a huge competitive advantage, how to win a better competitive position through continuous technological innovation, product upgrading, is the industry has been discussing the problem.

Information security challenges, with the popularity of industrial control products in the Internet era, product development must be closely related to network security. In the digital age, the network interconnection of industrial control system has become an inevitable trend, but also brings more information security risks. In response to network breakthroughs, black industry violations, external attacks, malware and other attacks, preventing information security has become a major challenge in the industrial control industry.

The talent shortage challenge, the industrial automation industry is closely related to virtualization technology, the Internet of Things, 2D/3D modeling and other technologies, which puts higher requirements on the professional skills and comprehensive quality of engineers. At present, the shortage of talent training in this area still exists, resulting in a shortage of talent resources. In order to achieve high-quality development of the industry, it is imperative to strengthen talent training and promote the sustainable, healthy and long-term development of industry talents.

- •The role of industrial computer

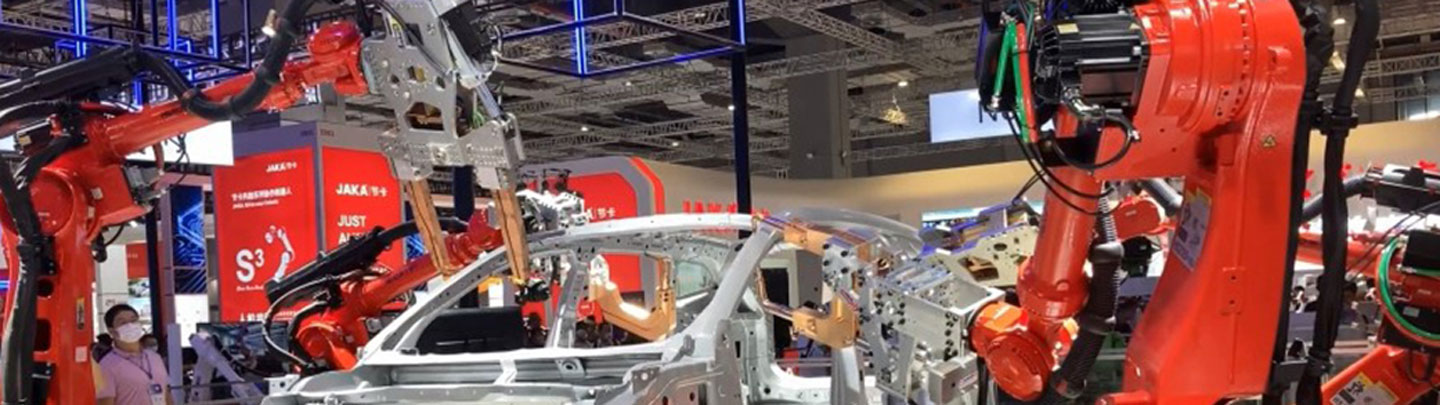

Industrial computers play a key role in the field of industrial production automation. They can be connected to various sensors, actuators and control devices to monitor, schedule and control the production process. Preset control procedures and algorithms, industrial computers can achieve intelligent management of production lines and improve production efficiency and product quality. Industrial computers can be used for real-time monitoring and remote maintenance of equipment.

- •Industrial computer advantageIndustrial computers are industrial control computers, which are a general term for tools that use a bus structure to detect and control industrial production processes, electromechanical equipment, and process equipment. Compared with ordinary computers, industrial control computers have stronger security, stability, and anti-interference capabilities. They also have waterproof, dustproof, and corrosion-resistant properties, and can adapt to the special requirements of industrial production environments.