Overcoming Size Limitations: Mini-ITX Motherboards for Industrial Automation Solutions

In rapidly evolving industrial landscape, automation has become a key driver for increased productivity and efficiency. As industries strive to optimize their operations, the demand for compact and powerful computing solutions has grown exponentially. YENTEK®, a leading high-tech enterprise, has emerged as a pioneer in the development of Mini-ITX motherboards for industrial automation solutions. In this blog post, we will explore the significance of Mini-ITX motherboards and how they enable businesses to overcome size limitations while enhancing their automation capabilities.

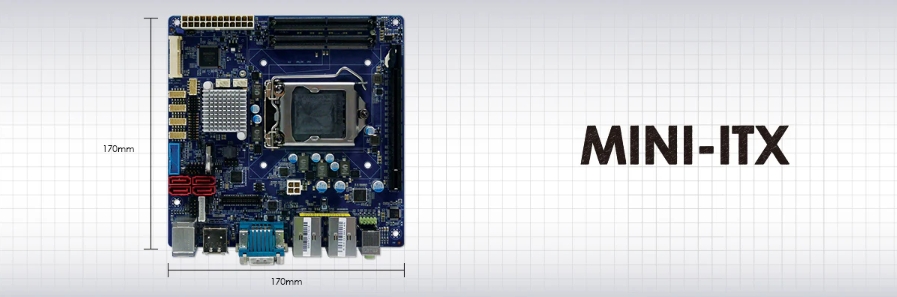

Understanding Mini-ITX Motherboards

Mini-ITX motherboards are compact, yet highly functional computing platforms designed to fit into small form factor cases. Despite their small size, these motherboards offer a wide range of features and capabilities, making them ideal for industrial automation applications. YENTEK® has leveraged its expertise in research and development to create Mini-ITX motherboards that deliver exceptional performance, reliability, and flexibility.

Compact Size, Powerful Performance

One of the primary advantages of Mini-ITX motherboards is their compact size. These motherboards are significantly smaller than traditional ATX or micro-ATX motherboards, allowing them to be easily integrated into space-constrained industrial environments. Despite their small form factor, YENTEK® Mini-ITX motherboards are equipped with powerful processors, high-speed memory, and advanced graphics capabilities, ensuring seamless operation of automation systems.

Versatility and Expandability

YENTEK® Mini-ITX motherboards offer a wide range of expansion options, enabling businesses to customize their automation solutions according to their specific requirements. These motherboards feature multiple expansion slots, including PCIe, Mini PCIe, and M.2 slots, allowing for the integration of additional functionality such as wireless communication modules, storage devices, and specialized I/O cards. This versatility ensures that businesses can adapt their automation systems as their needs evolve.

Enhanced Connectivity

Connectivity is a crucial aspect of industrial automation solutions. YENTEK® Mini-ITX motherboards are designed with a comprehensive range of connectivity options, including USB ports, LAN ports, serial ports, and audio jacks. This extensive connectivity enables seamless integration with various industrial devices, sensors, and control systems, facilitating efficient data exchange and communication.

Robust and Reliable

Industrial automation environments often involve harsh operating conditions, including extreme temperatures, vibrations, and dust. YENTEK® Mini-ITX motherboards are built to withstand these challenging conditions, ensuring uninterrupted operation in demanding industrial settings. These motherboards are designed with high-quality components, advanced thermal management systems, and ruggedized construction, guaranteeing long-term reliability and durability.

Simplified Maintenance and Serviceability

YENTEK® Mini-ITX motherboards are engineered with user-friendly features that simplify maintenance and serviceability. These motherboards are designed for easy access to components, allowing for quick replacement or upgrades. Additionally, YENTEK® provides comprehensive technical support and after-sales service, ensuring that businesses can rely on their automation systems without disruptions.

Conclusion

YENTEK® Mini-ITX motherboards have revolutionized the industrial automation landscape by overcoming size limitations and delivering exceptional performance in compact form factors. With their powerful capabilities, expandability, enhanced connectivity, and robustness, these motherboards enable businesses to optimize their automation solutions and achieve higher levels of productivity and efficiency. As industries continue to embrace automation, YENTEK® remains at the forefront of innovation, providing cutting-edge Mini-ITX motherboards that drive the future of industrial automation.

Solving Space Constraints with Mini-ITX Motherboards in Small Form Factor Builds